Production of Brass Rods

As one of the rare factories that produce its own raw materials, we produce 500 tons of brass rods per month in our Russia and Turkey/Dilovası facilities. Since the quality of the rods entered into production and the cost advantage directly affect our product quality and prices in the next stages, it gives us the opportunity to offer quality products to our business partners at the best prices.

The high-quality CW617 brass alloy we use in production enables us to produce more durable products, while allowing our products to be used safely in drinking water with the lead content according to RoHS standards.

Production of Brass Fittings and Inserts

With our wide machine park, while creating Emirplast's wide product range, we are also supplying brass semi-finished products to the leading plastic pipe systems manufacturers in Europe, Russia and the Middle East for nearly 20 years.

We provide our business partners durable, thoughtfully designed, brass fittings, underfloor heating fittings and valves at affordable prices ensuring that they are one step ahead of the brands that only have plastic pipe systems, as a brand of Güray Metal Plastik A.Ş., which has gained trust in more than 40 countries with its quality, price policy and after-sales relations.

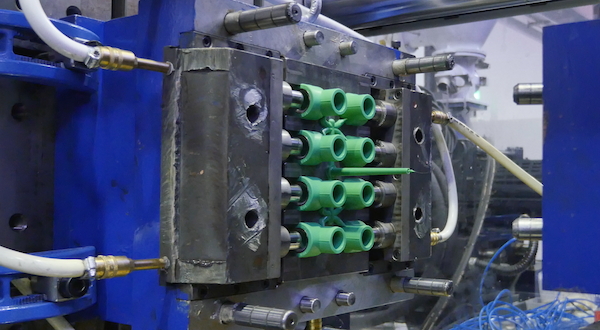

Polypropylene (PPR) Pipeline Systems

In 2016, we laid the foundations of the Emirplast brand on the way we set out to produce specific products that they could not produce for our customers, who produced Polypropylene pipes and fittings in 2012, under their own brands. With our more than 250 molds and wide machine park, we, as Emirplast, are one of the brands with the most product variety in the field of PPR pipes and fittings in Turkey. With the experience we have gained from different countries and manufacturers in 20 years, we design and produce safe products for our customers that they will not pay unnecessarily and have no problems. We use only the best raw materials in the world, such as first quality Borealis, Bourouge, Lyondell Basell, without sacrificing quality for price.

Laboratory and Quality Control

Thanks to our four-stage control system and our qualified engineers, we aim to maximize pre-shipment detections and minimize the complaints from the end consumer.

- Detection of raw materials that do not meet the standards with the barcode raw material input system,

- Detection during mass production with critical measurement control every half hour during production,

- Detection of ready-made products by visual control during the preparation process for shipment,

- In our laboratories equipped with modern and technological test equipment and complying with ISO standards, design controls before mass production and random product selection during mass production.